|

|

|

The Mighty Ingersoll-Rand Imperial Type 10 Compressor

|

| |

|

Just a quick note. I no longer own the Ingersoll-Rand compressor. Parted with it only

very reluctantly after loosing its free storage spot. I could have moved it to our land

in town, but it would have required very substantial effort, including installing a

culvert to get it over a ditch and tucked out of sight on the back twenty acres.

After my buddy Bill - who's sandblasting operation the compressor was bought for -

pulled stakes and headed for South Dakota, there was no chance I would ever use it for

anything. Could not justify the expense of moving it, so I put it up for sale and found

what I hope will be a very good home for it with a father and son team that is putting

together a working line-shaft machine shop museum. They felt the compressor would be an

excellent period piece to add to the collection and they look to me like they have the

gumption to make it happen, so...

Very sad to see it go, but if I get to watch it chugging away at their museum, that'll

be a pretty good feeling. Better than having it rot forever under tarps in the woods.

Life is regrets and compromises.

I kept the super cool relief valve and the mind blower 2400 Lb two phase (yup, two phase)

40 HP, 800 RPM electric motor. They wanted that motor, but I've got to have some momento

of a most fabulous machine I once owned. I'll tell you that motor was a trial to move.

More on all of that when I get a chance.

|

|

| |

|

This page was quickly slapped together to supply some pictures to the folks at the great

mine exploration forum,

www.aditnow.co.uk,

where I found a fair bit of interest and information regarding the Ingersoll-Rand Imperial

Type 10 two stage compound compressor. Forgive any misspellings or poor format. Just wanted

to get a few pics posted and don't have time for the niceties.

This compressor is even rarer a bird than old Dodge Power Wagons and Zundapp KS601's, and

any kind of information is about as common as hen's teeth, so I also hope this page will attract

others who are interested in these beautiful machines and might be able to supply some

additions to my very patchy knowledge.

The Ingersoll-Rand Imperial Type 10 Compressor - At its new home...

The Story Begins - Western Machine Tool Works

In Holland, Michigan, USA, there was for many years the Western Machine Tool Works. As the

name implies, they built machine tools, big ones - shapers, radial arm drills, horizontal

mills, etc. - and they did so until around 1980, at which time the factory closed, leaving

in place all of the equipment as though it were expected everyone would come back on Monday.

What makes this unique is that the equipment used there dated from the late 1800's and early

1900's. We're talking huge radial arm drill presses, Cincinnati universal mills, Fellows

and Gleason gear shapers, very large planers with beds around twenty feet long, shapers - the

list goes on - all in very servicable, if grubby as hell, condition.

More, much of the equipment was driven by line shafts till the end, and the plant had its own

motor-generators to supply the two phase power that everything ran on. The only trace I've

been able to find on two phase is the city of Buffalo, New York which used it in some areas.

This is an issue to me because I later came into possession of some of that equipment, in

addition to the compressor featured on this page.

In 1999, all of this was auctioned off except a few prize pieces that were to be retained

for a museum that was planned for a corner of the building. The City of Holland intended

to renovate the factory into lofts, restaraunts, etc. By 2003 it was pretty clear this

intention, if it ever truly existed, was no longer in effect. The property fronted Lake

Macatawa, nearly in downtown Holland, and various folks got to thinking knocking down the

fabulous old building - with its stained glassed office, mahogany banisters and wainscoting,

massive timbers, wood floors, and irreplacable history - was the more profitable route.

The auction/sale was to last four days. I took a day off work figuring I'd just wander around in

the building since it had always fascinated me. I worked just down the street for years and

would drive past the cavernous wooden doors on the way home at night. Inside you could just

barely make out the shapes of exotic machinery from days gone by.

I was one of a small group, maybe twenty people, standing at those doors on a rainy morning,

waiting for them to open and the sale to begin. Smaller stuff was tagged. Larger machinery

was to be bid on over the telephone.

The city hired Jeff DuPilka, who owns

West Shore Services, as master of

ceremonies. Check out his website, although it doesn't begin to do justice to the stuff

this guy pulls off and the enthusiasm he brings to the project.

Anyhow, whether they knew it or not, the city could not

have made a better decision. Jeff loves this old stuff and chose an impressive group of like minded

individuals to assist. He let us in out of the rain, then turned us loose into what still rates

as one of the most awe inspiring experiences of my life. So much so that I attended not just

part of that day, but the whole day, and not just that day, but all four days of the sale. I was

with the first to arrive in the morning and one of the last stragglers at night.

Western Machine Tool Works did nearly everything in house. They had monoliths of mahogany in

the basement where it was used in the pattern making department. At that time there was a foundry

just a half mile or so away, so the actual casting was done there. They made the gears, they

made everything. And supplying air for the entire operation was the Ingersoll-Rand Imperial Type 10...

|

|

|

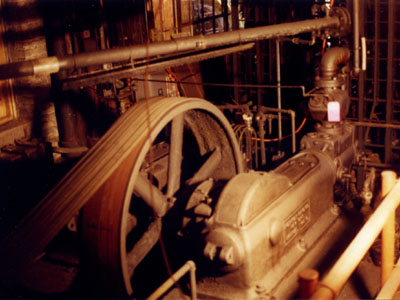

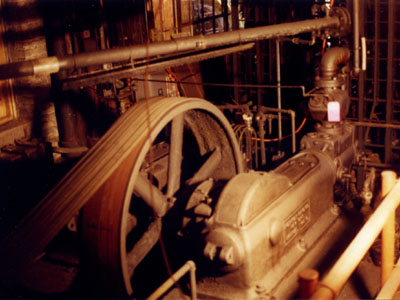

The factory had been boarded up for years and was dark as a tomb. This, and most of

the following pictures, was taken freehand in existing light (I just don't do flash)

on my trusty old Canon AE-1 with ASA 400 film, just prior to my going digital. Light was

from one trouble light hanging on a pipe. Wish I'd gone digital earlier. Would have

saved me a few hours of scanning this morning (yah, got lots more pics!).

You can see the flywheel is driven by eleven individual V-belts. The surface of the wheel

is machined with a crown of perhaps slightly north of 3/8", so it was originally designed

for use with a flat belt. They apparently had to at least partially disassemble the flywheel

to install or remove the V-belts. One way or the other the high and low pressure cylinders

must run on independent crank shafts also, with the flywheel acting as a kind of coupling

between them, or you couldn't slip the belts on.

The low pressure cylinder and crank housing is nearly completely hidden behind the

flywheel, but is very similar to the high pressure side, just considerably larger.

|

A view of the Imperial Type 10 from the flywheel end, showing

A view of the Imperial Type 10 from the flywheel end, showing

the flywheel itself, the valve housing above the high pressure

cylinder, and the long heat exchanger (looks like a pipe) leading

back left to the huge hand riveted iron receiver.

|

|

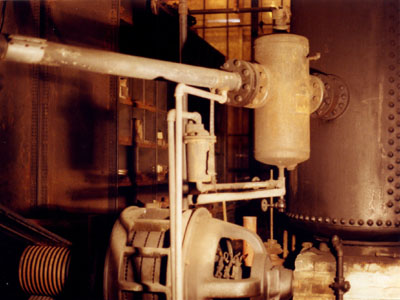

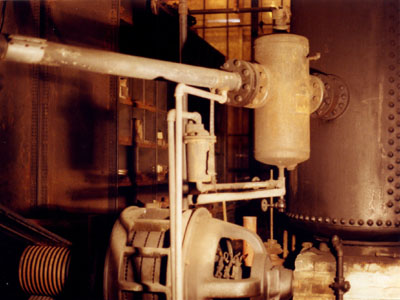

This view, over the top of the low pressure cylinder, shows the huge 2400 pound two

phase 40 horsepower motor. Talk about an odd beast. I found the catalog for the motor

upstairs in the file cabinets of the engineering department.

The flywheel is around five feet, a little over a meter and a half, in diameter, just

to lend some scale to what you're looking at.

You can see a little of the lubricator lines hard left in the image and, above the

compressor, the pipe-like heat exchanger running back to the water seperator. The

receiver is just out of the picture to the right.

Not shown in the pictures are the linkages for the valves which appear to be something

akin to those on a Corliss steam engine; rotating spools, each operated by a push rod

riding on an eccentric which is just outboard of the flywheel, one on each side. You can

see the low pressure eccentric cover immediately to the right of the flywheel with the

larger crank cover next to it.

|

A view from the low pressure cylinder

A view from the low pressure cylinder

back toward the motor and receiver.

|

|

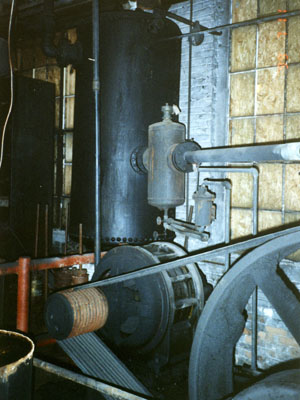

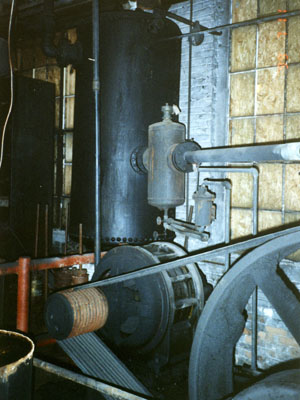

A closer look at the motor, water seperator and, finally, a look at the incredible

receiver.

Talk about something that is totally worthless! Would you put even twenty Psi in this

receiver? And it weighs a ton (literally, maybe more). But I cannot compell myself to

part with it. Rolled sheet iron, hand riveted, about three feet in diameter, around

a meter, and eight feet tall, around 2.5 meters. This mutha is big.

What you can't see in the picture is the relief valve. You can see a bit more of it

in the following picture. It looks like an old hanging scale, with a large

lever about three feet or one meter long extending from the valve body, bearing

down on the relief valve itself, up close to the pivot pin for plenty of leverage,

and a large cast weight hanging from the other end. The weight can be moved to any

of a number of notches on the arm, just like a scale weight, to set the relief pressure.

|

The motor, water seperator, and receiver.

The motor, water seperator, and receiver.

|

|

This is a picture that Jeff DuPilka supplied me years later when all the choice

equipment that had been saved for the museum was sold off when the museum plan fell

through. I was one of the lucky ones contacted and bought a Steptoe 15" shaper and

15 ton Atlas compound arbor press, one of my most treasured tools, in that quite

little sale. Jeff made sure everything went to people who would love it.

At the top center of this image you can see the relief valve I was going on about,

above. The weight is visible at the end of the arm against the light brick.

Forgot to mention above that the compressor itself weighs 9500 pounds. Jeff's guys

had an incredible Caterpillar TH83 all terrain telescopic forklift that was quite something to

see at work. The driver, Greg, estimated the compressor weighed about 9000 pounds.

He said, just a minute and we'll see. He lifted it with the Cat and reported it was

9500 pounds, so apparently the Cat had a load cell or something to tell him what

he was dealing with. Pretty good guess too!

|

Another view of motor and flywheel. Note the

Another view of motor and flywheel. Note the

massive receiver against the wall.

|

|

| |

Last updated 03-10-16

Email:

mechanique at wmol dot com

|

|

|

|